TM

11-5835-243-34/EE641-AA-MMl-010/E154

MTT/TO

31S3-4-110-1

displaced signal. Measure the period from start of

(6) Measure record period over which initial

sweep to the center of time jittered initial signal

signal transition is time jittered (fig. 3-6, dynamic

transition (fig. 3-6) for 10 seconds minimum, at the

skew). Verify that the dynamic skew does not ex-

end of tape, center of tap, and beginning of tape

ceed 7.5 microseconds.

Record the maximum period. Verify that reverse

NOTE

static skew is 0.0 6.0 microseconds.

Do not allow tape transport to go into

e. Forward/Reverse Skew Comparison. Deter-

rewind status.

mine algebraic sum of forward and reverse static

(7) When EOT status is indicated, depress

skew measurements taken in tests in para c and d

STOP switch on exerciser. Observe that PARITY

above. Verify that total static skew does not exceed

ERRORS counter displays zero error.

0.0 4.0 microseconds.

d. Reverse Skew.

(1) Depress RUN REVERSE switch on

3-20. Tape Transport Troubleshooting

exerciser. Observe the two channels displayed on

When a tape transport fails any of the functional

oscilloscope and select either CH1 or CH2

troubleshooting tests in paragraphs 3-9 through

TRIGGER that allows the positive-going edge of

both signals to be displayed.

been completed, perform entire test to verify the

NOTE

repair.

The skew measurement to be recorded in

step (2) is used in para e below. If sweep is

CAUTION

triggered by CH1, the measured period is

When troubleshooting the tape transport,

assigned a positive (+) value. If triggered

observe all safety precautions. Discon-

by CH2, measured period is assigned a

nect electrical power unless performing

negative (-) value.

service required electromechanical or

(2) Observe time displacement of the most

electronic actuation.

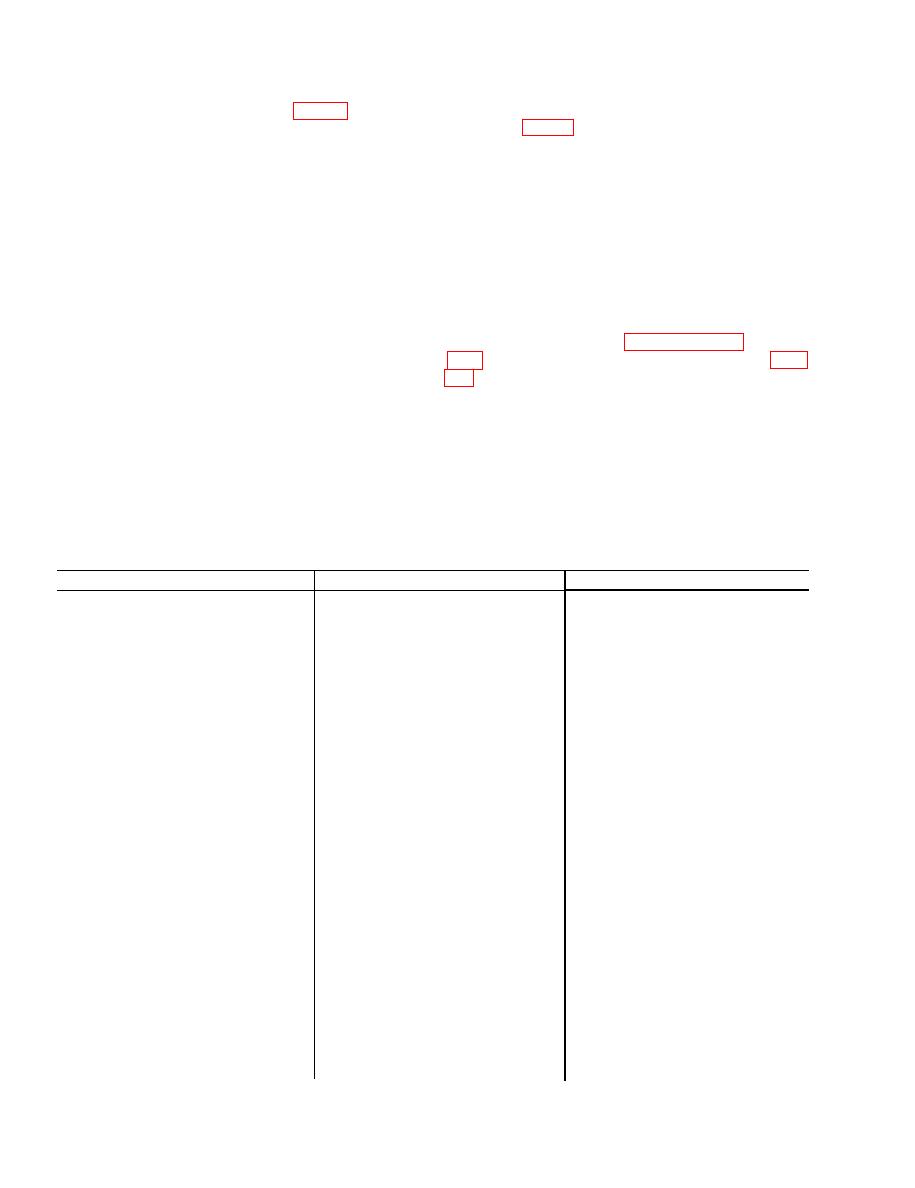

Table 3-2. Tape Transport Troubleshooting Chart

Probable cause

Action

Trouble

SELECTED status light on exerciser

Unit not selected.

Check SELECT switch. select line must

be low.

off.

Replace A4 assembly.

Control logic bad.

Install cartridge.

READY status light on exerciser off.

Cartridge not installed.

Check SELECT switch. Select line must

Unit not selected.

be low.

Replace switch.

Cartridge in place, interlock switch

bad.

Access door not closed.

Close and lock access door.

Replace switch.

Door closed, interlock switch bad.

Wait to complete rewind.

Unit is rewinding.

Replace A4 assembly.

Control logic bad.

Install cartridge.

REWIND status light when

RWND

Cartridge not installed.

Position tape away from BOT.

Tape in cartridge is at BOT.

switch inside door is pushed.

Replace switch.

RWND switch bad.

Replace A4 assembly.

Control logic bad.

Install cartridge.

REWIND status light off when commended

Cartridge not installed.

Position tape away from BOT.

Tape in cartridge is at BOT.

to rewind.

Close and lock access door.

Access door not closed.

Command unit to stop.

Unit is in run command.

Install new tape in cartridge.

B O T status light off after complete re-

No BOT strip.

Installed new sensor and LED.

wind when commanded to stop.

Strip sensor or LED bad.

Replace A5 assembly.

BOT status light off after complete

Servo control bad.

Replace A4 assembly.

rewind.

Control logic bad.

Install new tape in cartridge.

EOT status light on exerciser off when

No EOT strip.

Install new sensor and LED.

at EOT.

Low tape sensor or LED bad.

Strip sensor or LED bad.

Replace A5 assembly.

Servo control bad.

Replace A4 assembly.

Control logic bad.

Clean commutator or replace brushes.

Unit goes into rewind status before given

Servo motor has noisy brushes.

rewind command and before EOT is

Install new tape in cartridge.

reached.

Cartridge has worn tape.

3-12