TM

11-5835-243-34/EE641-AA-MMl-010/E154

MTT/TO

31S3-4-110-1

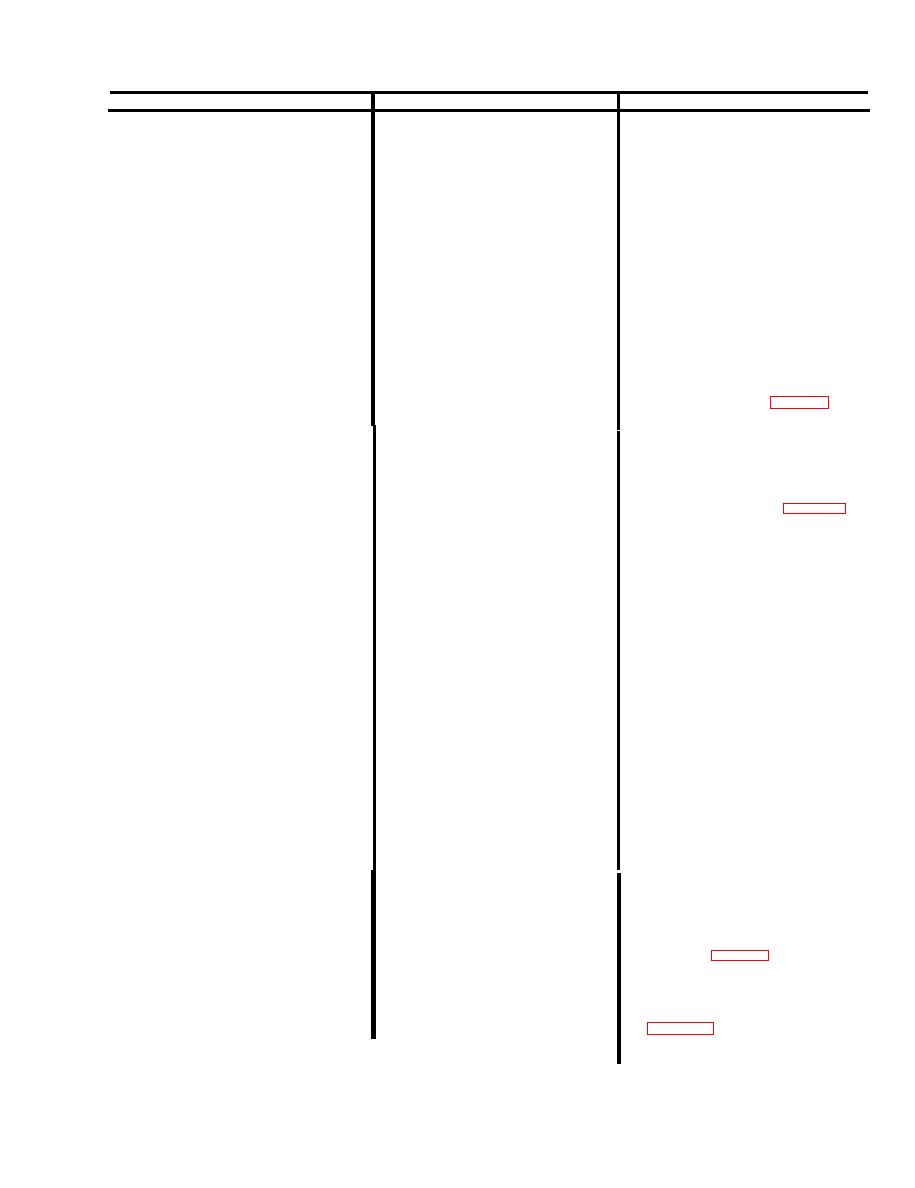

Table 3-2. Tape Transport Troubleshooting ChartContinued

Probable cause

Trouble

Action

Replace A5 assembly.

Servo control bad.

Control logic bad.

Replace A4 assembly.

Make EOT holes in tape.

Tape runs off end roller on cartridge.

No EOT hole on tape.

Low tape sensor of LED bad.

Install new sensor and LED.

Install new sensor and LED.

Hole sensor or LED bad.

Motor turning in wrong direction,

Reverse tach and motor leads.

Replace A5 assembly.

Servo control bad,

Replace A4 assembly.

Control logic bad.

Tape runs off beginning roller on

No BOT hole on tape and no BOT

Make BOT hole in tape and install

cartridge.

strip on tape

BOT strip.

Install new LED and sensor.

LED for hole and stip bad.

Replace A5 assembly.

Servo control bad.

Replace A4 assembly.

Control logic bad.

Motor not in phase with tach.

Reverse tach or motor wires.

Motor speed cannot be controlled (runs

away).

Servo control bad.

Replace A5 assembly.

Tach winding open.

Replace motor/tach.

Motor winding open.

Replace motor/tach.

Motor can be turned by hand with no resist-

Replace A5 assembly.

ante, with power on and in stop mode.

Servo control bad.

Power amplifier bad.

Check A9 assembly per table 3-3; repair

by replacing components.

Tape bunched up in cartridge.

Replace cartridge.

No tape motion when in run command with

Motor seized.

Check motor.

cartridge in place and door closed and

Replace A5 assembly.

select line low.

Servo control bad.

Replace cartridge.

Cartridge worn or belt and idler wheel

Tape bunches up in cartridge.

damaged.

Unit does not run at correct speed (LSV

1. Adjust A5 assembly per para 3-24.

Servo control bad or not calibrated with

2. Replace A5 assembly.

motor/tach.

too great); LSV > 3% or only one speed.

3. Replace motor.

Read permit line must be low.

Unit not commanded to read.

Unit will not read from skew car-

Check tape motion.

No tape motion.

tridge tape.

Check control logic assembly A4. Check

No clocks but data is present on TP4,

TP5 and TP6 of read/write circuit

read/write circuit cards by in-

cards.

terchanging.

Clean head.

No data present at read/write circuit

card.

Write permit line must be low.

Unit not commanded to write.

Unit will not write data.

Write reset must be high.

Unit in write reset mode.

Dirty head.

Clean head.

Enable cartridge,

Cartridge not write enabled.

No tape motion.

Check tape motion trouble.

No input signal.

Check exerciser input controls and data

signals to cartridge recorder.

Replace A4 assembly.

Control logic bad.

Check read/write circuit cards by

Read/write circuit card(s) bad.

interchanging.

Clean commutator or replace motor.

Unit has excessive parity errors when read-

Servo motor noisy,

Replace tape or cartridge.

ing only or when reading while writing.

Tape damaged.

Clean head and guides.

Dirty head and/or tape guides.

Replace A4 assembly.

Control logic bad.

Power will not come on.

ON/OFF circuit breaker bad.

Check and replace applicable item.

Power supply bad.

Line filter bad.

Tape transport tape guide springs dirty.

Clean tape guide springs, run tape

Steps in tape.

cartridge to EOT and rewind.

Motor runs in one direction only.

Power amplifier bad.

Check motor drive voltages and operating

voltages per table 3-3.

Excessive skew.

Clean tape guides and capstan.

Guides dirty.

Reseat cartridge/align head.

Cartridge/head out of alignment.

Cartridge worn.

Replace cartridge.

Noise excessive after write reset ( >0.5 v

Perform erase verification procedure

Erase function/erase head.

peak-to-peak).

Write reset.

fault. If erase fails check erase signal or

replace head assembly (erase fault).

3-13