TM

11-5835-243-34/EE641-AA-MMI-010/E154

MTT/TO

31S3-4-110-1

Table 3-2. Tape Transport Troubleshooting ChartContinued

Trouble

Probable cause

Action

Instantaneous speed variation excessive

Motor/tach dirty.

Check tack ripple voltage (table 3-3)

(ISV not within tolerance).

(should be less than 200 mV). Clean

tach and/or motor commutators.

Replace motor assembly.

Power cycle test failed.

Ground wire loose.

Check ground points.

Tape transport current excessive.

Check power circuitry.

Short circuit.

Tape cartridge bad.

Replace cartridge.

Clean capstan.

Start/stop time excessive.

Capstan shaft dirty.

Replace cartridge.

Tape cartridge bad.

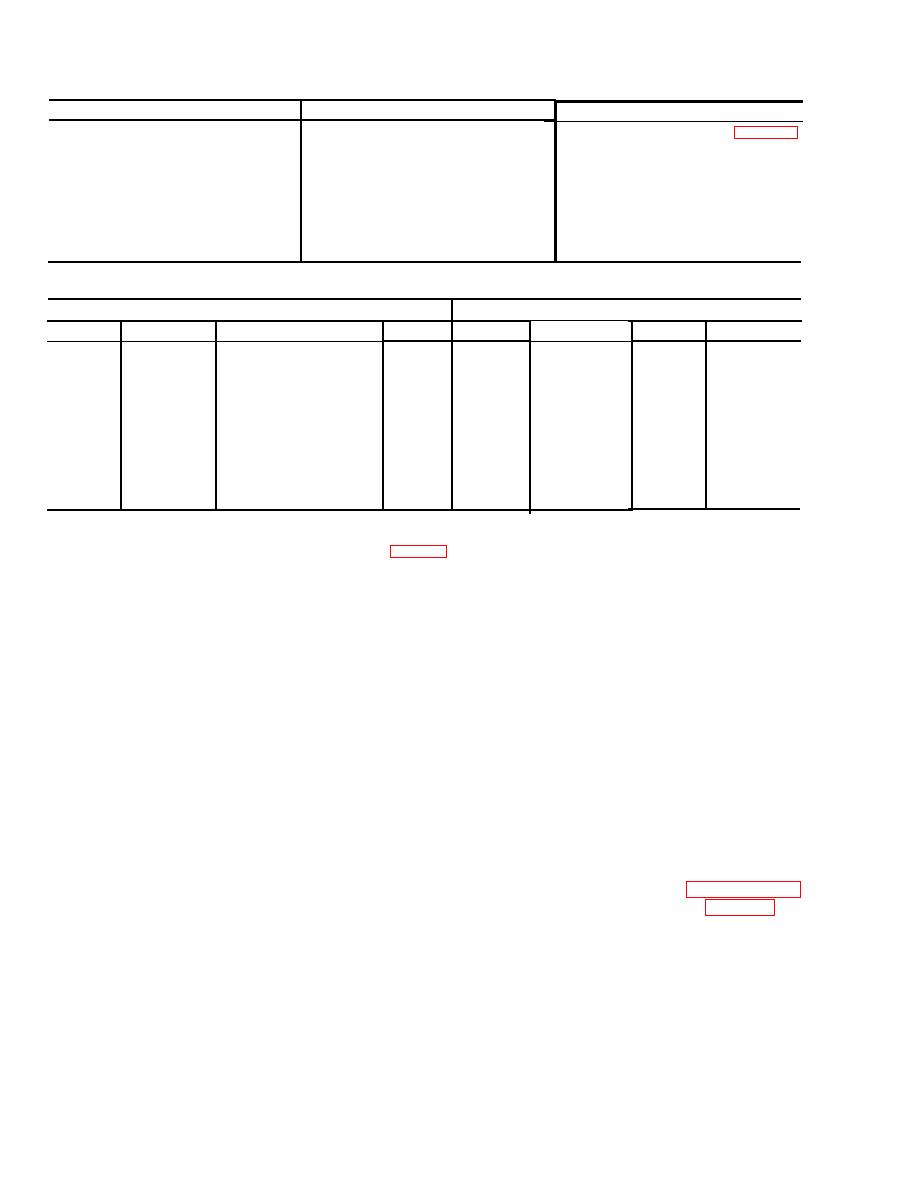

Table 3-3. Power Amplifier Operating Voltages

Speed and direction

Reference

FAST FWD

FAST REV.

FWD

Signal

Remarks

STOP

REV.

(Note 3)

+ 1.2

+1.4

A9A1B

0.5

0.6

0.6

Note 4 DRIVE A

GROUND

+1.3

+ 1.9

+1.9

Note 4 DRIVE B

0.2

0.4

A9Q7B

GROUND

4.1

+ 3.6

+5.7

A9Q5C

A9Q6C

0.0

6.3

Note 5 MOTOR DR

0.0

+ 0.9

+0.9

A9Q1E

0.0

0.0

GROUND

Note 6

+27.1

+27.0

+ 27.8

+27.5

+27.5

GROUND

A9Q2B

Note 6

+ 0.4

+0.4

A9Q3E

Note 6

0.0

0.0

0.0

GROUND

+ 0.1

+0.0

+ 1.3

+1.3

+0.7

A9Q7E

Note 6

GROUND

+ 0.6

+0.6

+ 5.2

+7.3

+0.6

A9Q6C

GROUND

Note 6

0.0

+0.6

GROUND

0.0

Note 6

+ 0.6

+0.1

A9Q5E

+6.2

+ 4.1

+ 0.9

+1.0

+0.2

A9Q6C

GROUND

Note 6

+4.8

+ 2.5

4.7

2.4

TP5A5

Note 7 TACH DR

TP6A5

0.0

NOTES

1.

Use power amplifier schematic diagram (fig. FO-5) in conduction with this table.

2.

All readings in vdc with cartridge near BOT. These voltages are approximate and only in-

dicate general operating levels.

3.

Ground is R6, pin 1.

4.

If DRIVE A or DRIVE B signals are absent, check input circuitry.

5.

If motor drive signal (output) is incorrect, check motor winding for short to ground or open

winding. If motor is OK, refer to note 6.

6.

If input signals are present but motor drive signals are incorrect, use these signal levels to

isolate the fault y piece part(s). Repair by replacing faulty component(s). If necessary, com-

ponents may be removed from card in order to test.

7.

Tach drive voltage is shown for reference only.

CAUTION

d. When BOT is reported, turn off TRANSPORT

When replacing power transistor, apply

power and reinstall cards A1, A2 and A3.

heat sync compound (Dow Corning #340

e. Set WRITE switch on exerciser off. Depress

Silicone) to the base of component.

RUN FORWARD. Observe that the signal present

at TP1, 2 and 3 of A1, A2 and A3 is broadband noise

3-21. Erase Verification

at an amplitude of approximately 0.5v peak-to-peak.

a. Turn off TRANSPORT power on exerciser and

3-22. Magnetic Tape Cartridge Troubleshooting

remove digital read/write circuit cards A 1, A2 and

A3.

When a magnetic tape cartridge fails any of the

b. Turn on TRANSPORT power.

functional troubleshooting tests in paragraph 3-19,

c. Depress WRITE (on) and RUN FORWARD

locate failure in "Trouble" column of table 3-4 and

take the specified action. When a repair has been

switches on exerciser. Mow tape transport to run

for one minute. Depress STOP then REWIND

completed, perform entire test to verify the repair.

switch on exerciser.

3-14