at least 20 db below the maximum signal (1/10

maximum value on the oscilloscope), it is neces-

a. Wafer Replacement. If a wafer is defective,

sary to improve the balance. This may require

it is easier to replace the wafer than to replace the

changing the photocell or checking the transmit-

entire switch and cable assembly. At the factory,

ting optical system. After proper contrast is

a special socket wrench (fig. 124) is used for re-

obtained between black and white, as adjusted for

moving the nuts of the entire switch assembly.

negative transmission, set the CONTRAST con-

Similar socket wrenches can be made easily in the

trol for positive transmission and obtain as good

field. If materials are not available, long-nosed

a balance on white as possible. Readjust the

pliers will serve the purpose.

balance by adjusting the sliding contact on R42.

b. Grounding Switch. A leaf switch is actuated

If further improvement is necessary, adjust the

by the selector switch when in the transmitting

value of R49, except in TT-1D/TXC-1, TT-1E/

position. This switch grounds the tip of the

TXC-1, and TT-1F/TXC-1 models, by changing

RADIO XMTR jack for the purpose of control-

the resistor to a higher or lower value. The

ling the power relays in the radio transmitter.

balance on either white or black copy of 20 db

Clean and burnish the springs. If proper opera-

below the maximum signal can be obtained by

tion is not obtained after cleaning the springs,

adjusting the CONTRAST control and the

they may be bent for better contact.

sliding contact on R42.

c. Sylus Actuating System. After working the

switch, be sure that the adjustments of the

stylus actuating system are not upset. If the

a. General. The alinement of the signal am-

stroke is too long, make correction by bending

plifier involves nothing more than step-by-step

the actuating arm attached to the selector switch.

checks of signal voltages and waveforms. If

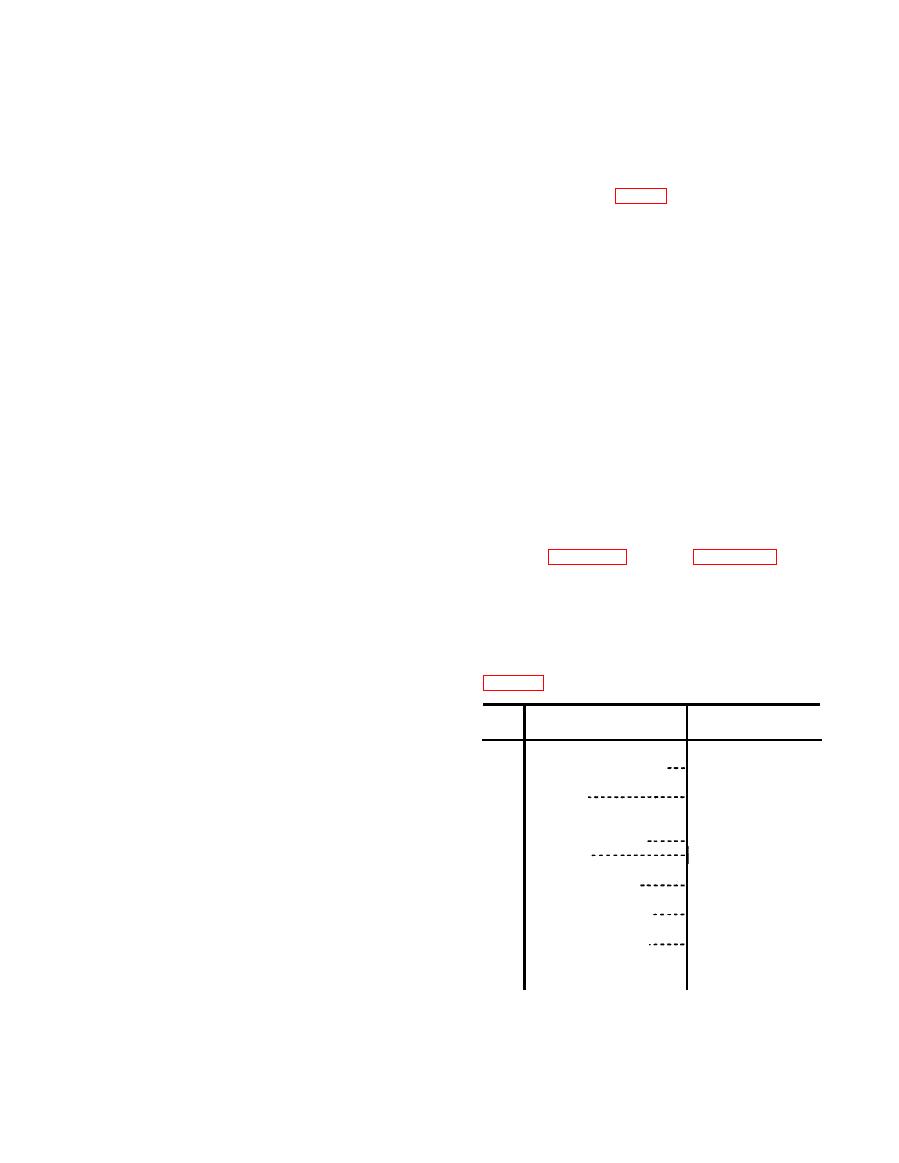

The stylus holder assembly for Facsimile Trans-

there is any deviation from the voltages in the

ceiver TT-1/TXC-1 through TT-1C/TXC-1 is

tracing chart, or if there is any tendency for the

shown in figures 125 and 126. Figure 127 shows

signal to flatten as shown by the oscilloscope,

the stylus holder assembly for Facsimile Trans-

locate the faulty stage and take corrective meas-

c e i v e r s TT-1D/TXC-1, TT-1E/TXC-1, and

ures. All parts may be replaced with approxi-

TT-1F/TXC-1.

mate equivalents, with the exception of trans-

former T2. In emergencies, this transformer can

ceivers TT-1/TXC-1, TT-1A/TXC-1, TT-1B/

be replaced with a driver transformer designed to

TXC-1, and TT-1C/TXC-1, Parts Description

operate into a 6N7 tube or a pair of 6V6 tubes.

Such a transformer should have a turns ratio of

1 to 1 for full secondary. Connect one-half of

the low impedance secondary of the driver trans-

Ref

Function

Name of part and description

Symbol

former to terminals 1 and 2. Leave the other

half of the secondary open. If such an emer-

Supports stylus nec-

STYLUS ASSEMBLY

gency replacment is made, low-voltage line ter-

dle.

minal connections may be obtained by using the

Conducts high volt-

A

STYLUS

a g e to recording

UC feed coil.

paper.

b. Stylus Transformer. Stylus transformer T3

Holder for stylus A.

B

HOLDER, stylus

should be replaced with an exact equivalent. In

Clamps stylus in

SCREW

C

an emergency, a driver transformer, such as one

holder.

designed to operate into a pair of 6V6 tubes or

D

PIVOT,

fixed

Left-hand pivot for

a single 6N7 tube, will serve the purpose. The

stylus shaft.

E

PIVOT,

adjustable

Right-hand pivot for

voltage breakdown rating of the transformer

Stylus shaft.

should be above 2,000 volts. The line side should

S P R I N G , bracket

Spring support for ad-

F

be connected to terminals 1 and 2. A line-to-line

justable pivot.

transformer may be used, but the recording will

BRACKET ASSEMBLY:

Supports pivote.

G

not be at full density.

including fixed pivot.