e. Lubrication. Erratic clutch tension usually

c. Binding. If the drum tads to bind on the

lead screw when it is turned or moved along the

indicates the need for lubrication. Refer to paar-

lead screw by hand, it is possible that the lead

graph 136.

screw is bent or nicked. A nick in the guide rail

f. Alinement of Shaft. For proper operation of

may cause binding. Do not blame the drum un-

the clutch and drive assembly, the shaft (M) must

be in alinement with the lead screw. The up-and-

less other repairs fail to solve the trouble. Binds

down alinement can be controlled in Facsimile

sometimes can be cleared by flushing the drum

bearings with solvent (SD) and relubricating with

Transceiver TT1/TXCl by the mounting screws

oil (PL Special).

of the motor, provided the motor has rubber

grommets in the mounting holes. Motors with-

and 118) is too loose and is free to move sidewise,

out grommets are machined in a jig and should

give no trouble in this respect.

jitters may occur in the recorded copy. If replace-

g. Dog Latch Cam Plate. Excessive wear and

ment parts are not available, a temporary repair

may be made by squeezing the walls of the key

damage are caused to the dog latch cam plate by

setting it improperly. The cam plate should be

retainer.

adjusted so that it first begins to trip the dog

latch after the dog latch haa traveled approxi-

occur in Facsimile Transceivers TT-1B/TXC-1

mately one-fourth of an inch past the end of the

through TT-1F/TXC-1, tighten the drum-tension

adjusting screw one-half turn. This is the upper

plate. The plate must engage the dog latch near

the tip to insure enough leverage. Adjustment

screw on the left-hand lead-screw bearing block

can be made by sliding the entire dog trip arm

(fig. 1 19).

assembly along the lead screw or by changing

f. Removal of Paper Clamp in Facsimile Trans-

shims under the cam plate. The dog latch and

ceiver TT1C/TXC-1.

trip arm must operate freely under a light tension

(1) To remove the paper clamp from the

from the springs.

drum, proceed as follows:

(a) Place a blunt instrument, preferably a

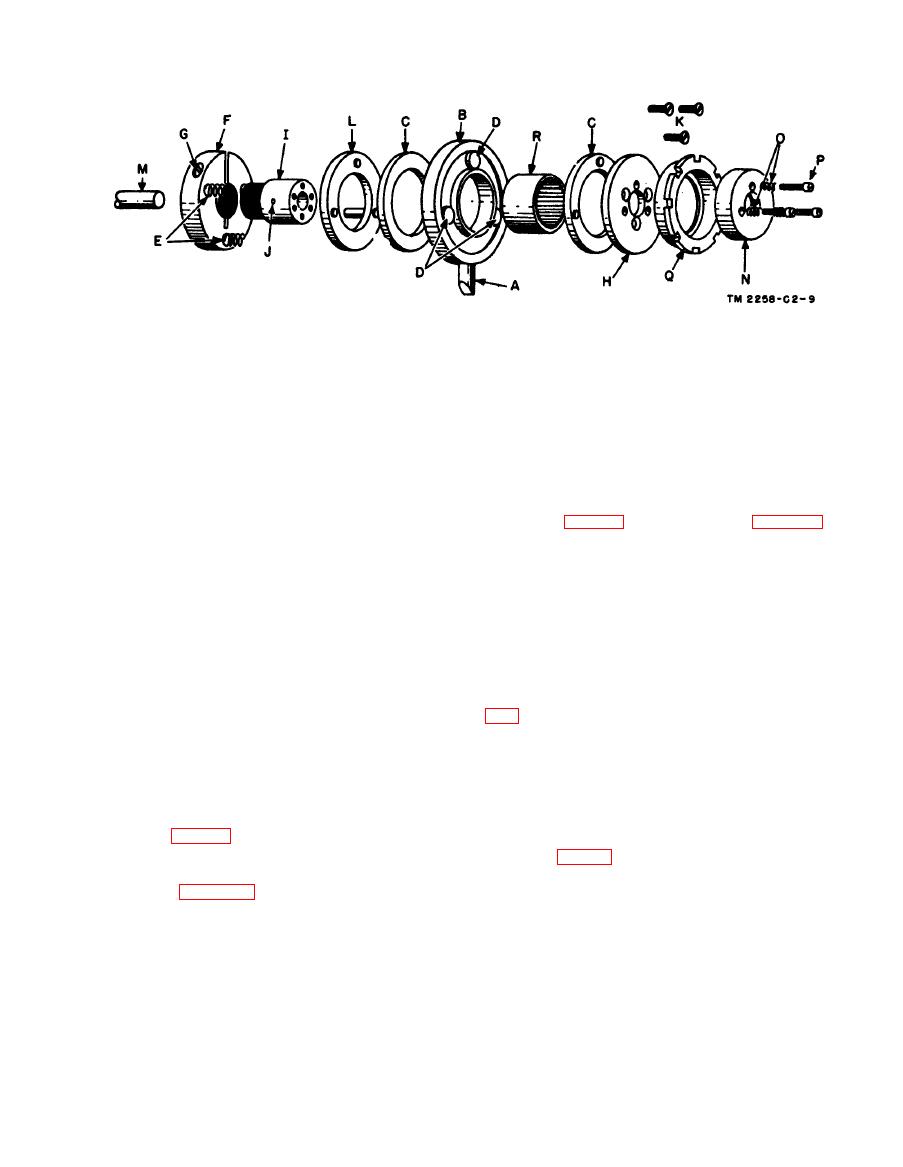

107. Drum

piece of hard wood, against the left-

hand edge of the paper clamp (C,

a. General. The drum of Facsimile Trans-

a hammer.

ceiver TT1(*)/TXC1 is constructed as illus-

trated in figures 117 and 118.

(b) Slide the paper clamp to the right about

b. Half Nuts. If the half nuts (split nuts) be-

one-half inch, then lift the clamp out

come damaged, replacement may be made from

of the drum.

(2) To remove the interred lever assembly,

the spares provided with the equipment. In

proceed as follows:

older equipments, each half nut holder is num-

bered. Later equipments will accept stock half

(a) Remove the knob on the right-hand

nub, and their retainers are lettered A and B.

side of the drum.

The half nuts must be matched with the corre-

(b) Remove the mounting plate and slide

spending markings on the retainer.

the assembly out of the drum.