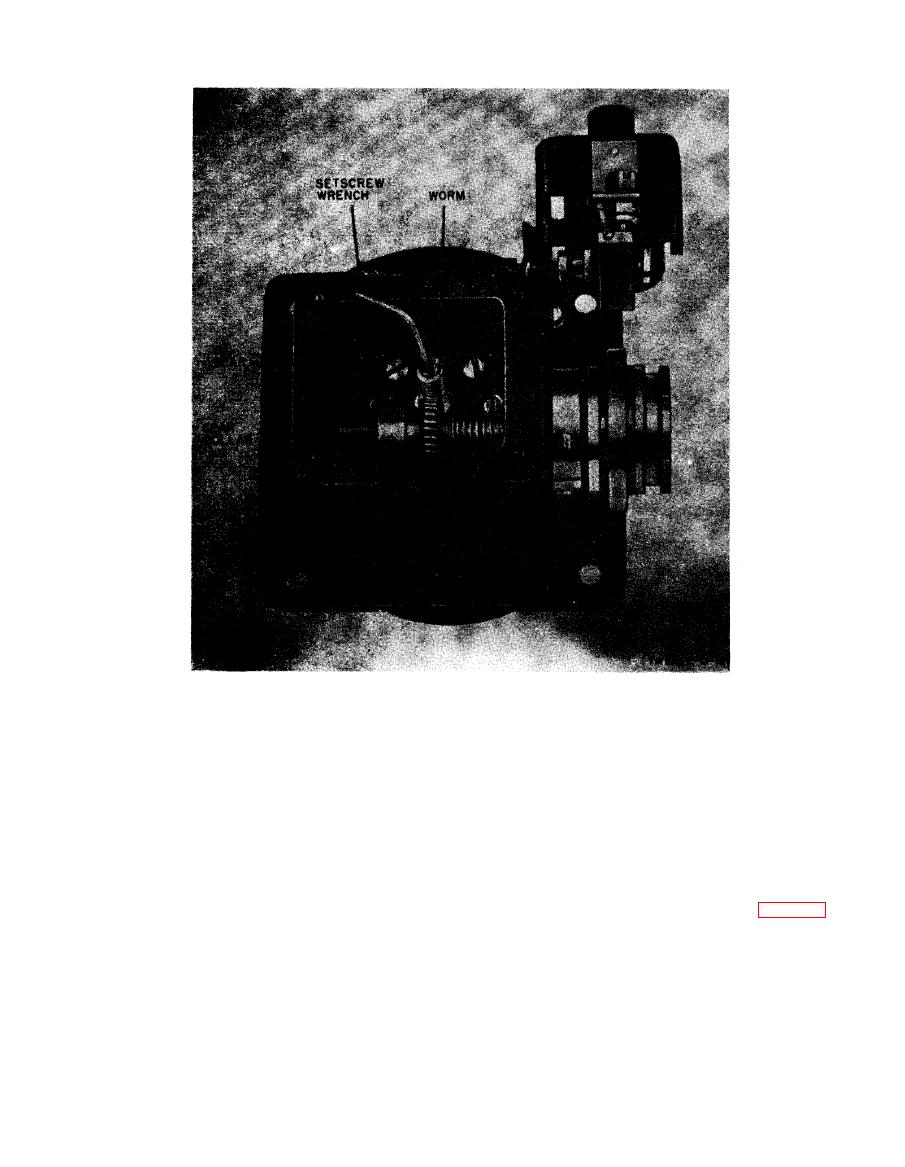

Figure 111.

No. 6 setscrew wrench inserted into worm.

primary clutch load may cause the motor to stall

all later models, tension is adjusted by turning the

during the phasing operation.

retainer on its screw thread.

Make a static

measurement of the secondary clutch tension.

Warning: Never run the motor with the clamp

screw (G) loose, or the gears may be stripped.

With the motor stopped, and the string wrapped

b. Secondary Clutch.

The secondary clutch

around the drum, pull the string to rotate the

tension should be approximately one-half that

drum while reading the scale. Be sure that the

of the primary clutch (6 to 7 ounces). In Facsimile

measurement is taken when the dog latch is

T r a n s c e i v e r s TT-1D/TXC-1, TT-1E/TXC-1,

engaged with the secondary clutch ring to obtain

and TT1F/TXC-1, the secondary clutch tension

a correct measurement. The secondary clutch

should be between 3 and 6 ounces. If the second-

tension is adjusted by means of screws (P, figs. 115

ary clutch is too loose, the stop arm and dog trip

and 116). If screws work loose, lock the heads in

will come together too rapidly and possibly throw

place with glyptal after making correct adjust-

the motor out of synchronism or slip the primary

ments. Before using glyptal, remove all grease

Clutch. Slipping of the primary clutch during

with solvent (SD). If the screws are of the slotted

the phasing operation will result in out-of-phase

type, spread the sides slightly by inserting a small

recording. If the secondary clutch tension is too

heavy, the secondary clutch load added to the

screw driver or knife into the slot.