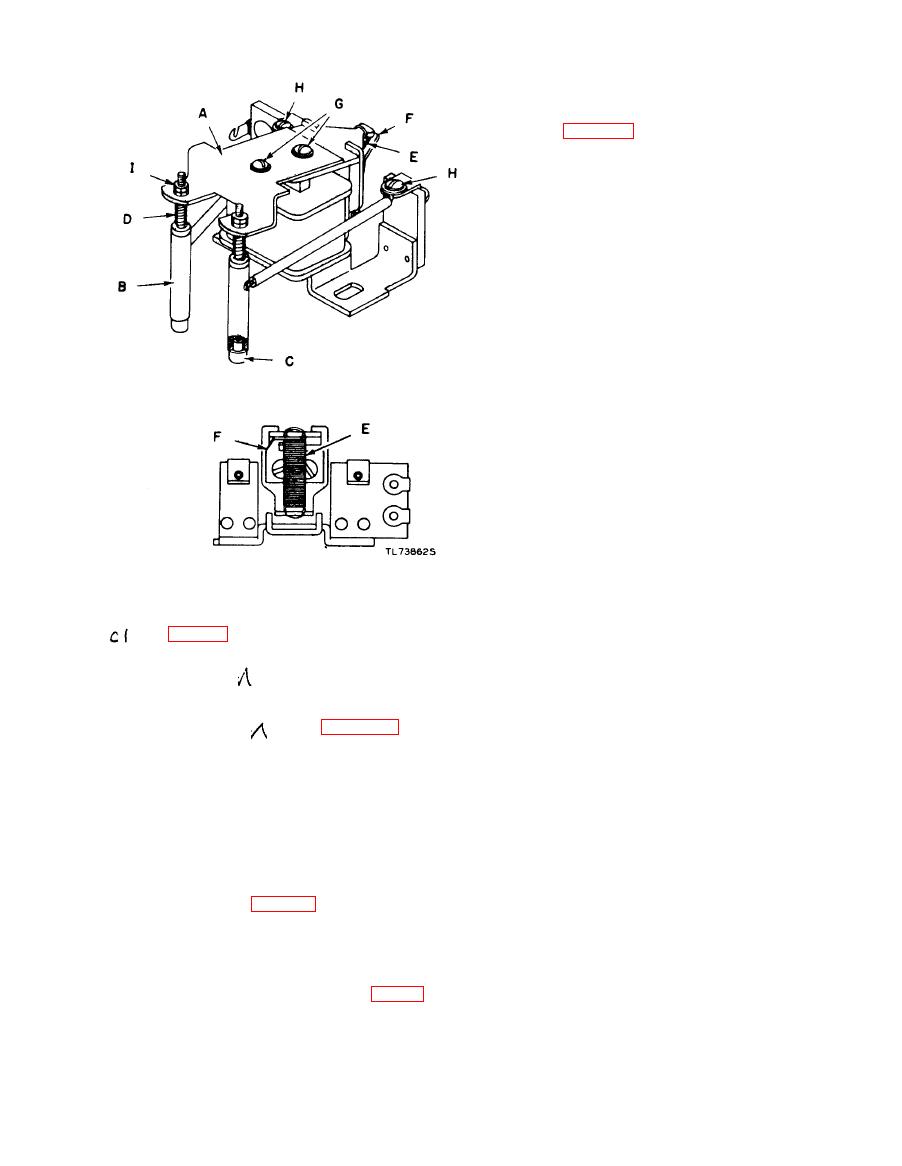

f. Remove the bearing, gear collar, and gear

from the countershaft with finger pressure applied

as shown in figure 112.

g. Remove the gear collar from the gear and

place this collar on the new gear.

h. Slide the assembly (gear collar and new gear)

onto the countershaft.

i. Inspect the bearing. Note that on one side

of the bearing the inner race is flush with the out-

side race. The inner race is recessed on the other

side of the bearing. Insert the bearing onto the

countershaft with the recessed inner race side

toward the outside of the gearbox (the side upon

which the bearing cover plate is mounted). Since

the inner race rotates with the countershaft, as-

sembly in this manner will insure against the inner

race rubbing on the bearing plate when the plate

is replaced.

j. Replace the bearing cover plate.

k. Center the gear (and the gear collar) on the

countershaft so that the gear is at the hole in the

motor shaft that receives the worm.

l. Place the new worm into the motor shaft hole

and tighten it with the Allen setscrew wrench and

the spanner wrench. The worm now should be

in mesh with the gear.

m. Move the gear (and the gear collar) along

the countershaft in either direction until it is

stopped by the worm. Now move the gear in the

other direction along the countershaft until it is

Synchronous Motor KBA-2

stopped by the worm. The distance of lateral

movement of the gear along the shaft allowed by

Normally, the gear should be replaced when the

the worm will be approximately one-sixteenth of

worm is replaced. Although the gear may not

an inch. Moving the gear one-half of this dis-

display excessive wear, it becomes, in time, charged

tance from either extreme will center the gear on

with abrasive particles which may cause undue

the worm.

wear on a new worm. Refer to figures 110 through

n. Tighten the gear-collar set screw.

113 before starting replacement. The motor may

o. The new worm must be mounted with partic-

be left mounted on the facsimile set during re-

ular orientation to the motor shaft where worm

placement.

and gear run smoothest. Turn the power on and

a. Remove the spanner wrench and the top

start the motor.

cover plate (four screws) from the gearbox. Re-

move the No. 6 Allen setscrew wrench (mounted

Note. There is danger of high-voltage shock when work-

ing near the motor with the power on. Use extreme cau-

on clip on gearbox).

tion when making adjustments described in the rest of

b. Insert the No. 6 Allen setscrew wrench in

this paragraph.

the taper screw of the worm, and grip the slot with

the spanner wrench (figs. 110 and 113).

p. With the motor running at synchronous

speed, place two fingers of the left hand on the

c. Loosen the taper screw, remove the Allen

wrench and the spanner wrench, and pull the

top of the motor gearbox, one finger above each

worm gear up out of the motor shaft.

countershaft bearing. The trembling sensation

d. Remove the bearing cover plate (four screws).

that will be felt must be minimized to insure

smooth worm and gear operation. (To ascertain