shaft can be replaced if suitable shop facilities are

available. Pin the new gear to the shaft with a

taper pin. Sometimes, a damaged gear can be

moved along the shaft and pinned in a new place

so that 23 good portion of the gear will mesh with

the worm.

return spring (H) must produce a strong spring

action. Replace the spring if the tension is too

weak. Pivots (F) and (G) must not cause binds

or side play. To adjust the armature backstop

(B), set up the transceiver for a receiving test

on a phasing signal. Proceed as follows: With

the PHASE button depressed, back off the ad-

justing screw until the armature fails to operate.

Screw in the armature back screw until the arma-

ture fails to catch the top arm. Return the screw

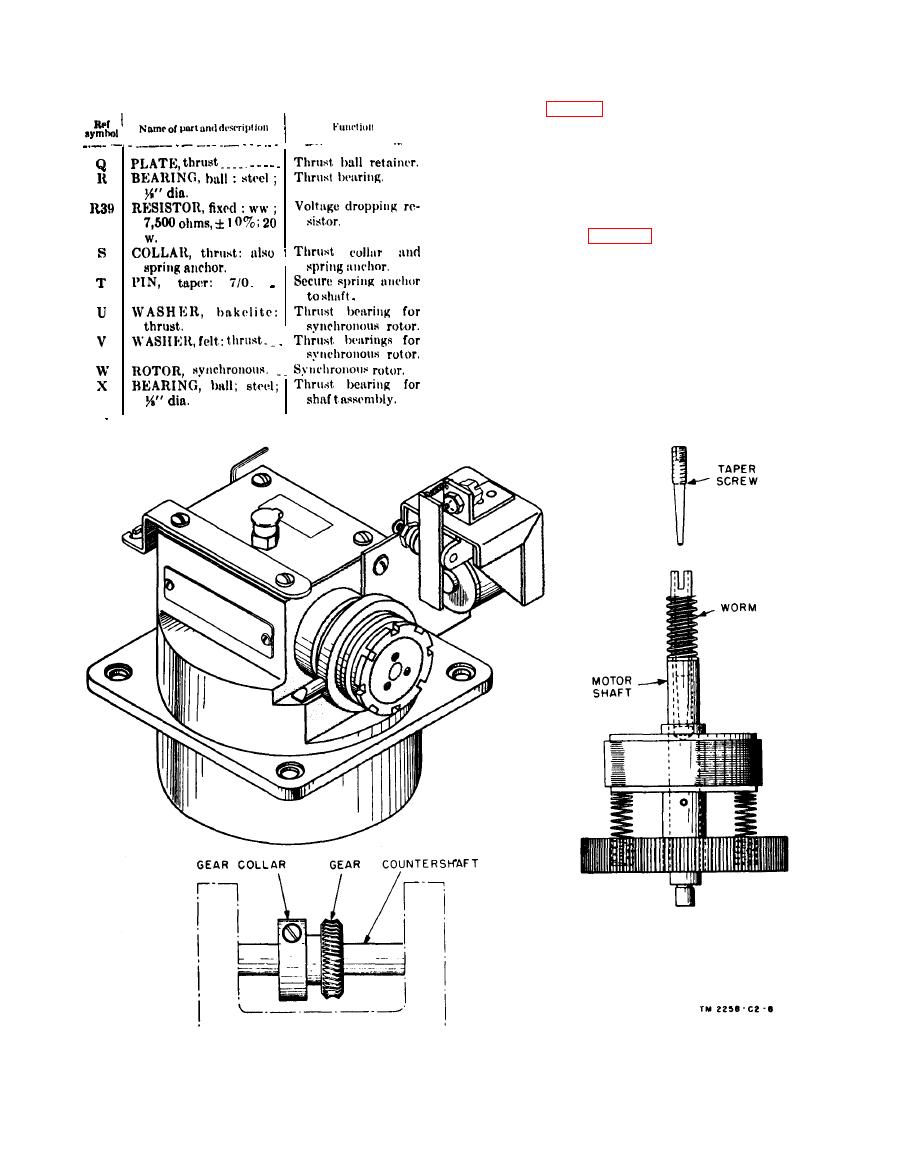

Figure 106. Synchronous motor, KBA-2.

146