.....

line should not deviate from its correct position

by more than the width of one recording dot or

elemental area. This is approximately one one-

hundredth inch. A bind in the drum and the

tudinal travel of the drum. If the drum does not

lead-screw system causes jitters which will be

advance uniformly at the rate of 1/96 inch per

aggravated considerably if the synthetic rubber

revolution, some of the photographically recorded

plate is too soft.

scanning lines will overlay and others will under-

lap, thereby creating a blank space between the

two lines. If the effect is great enough to cause

noticeable deterioration in the received copy, cor-

rective measures must be taken. The most

common cause of trouble is the drum and lead-

screw system. First check the arm of the drum-

feed engaging mechanism to be sure it is riding on

the guide rail. Install new half nuts as a correc-

tive measure. Be sure that the snubber (N, fig.

does not correct the trouble, make a test recording

by substituting the drum of another machine.

Be sure that the test recording is of the same type

and is made by the same method as the one on

which the line feed pattern proved troublesome.

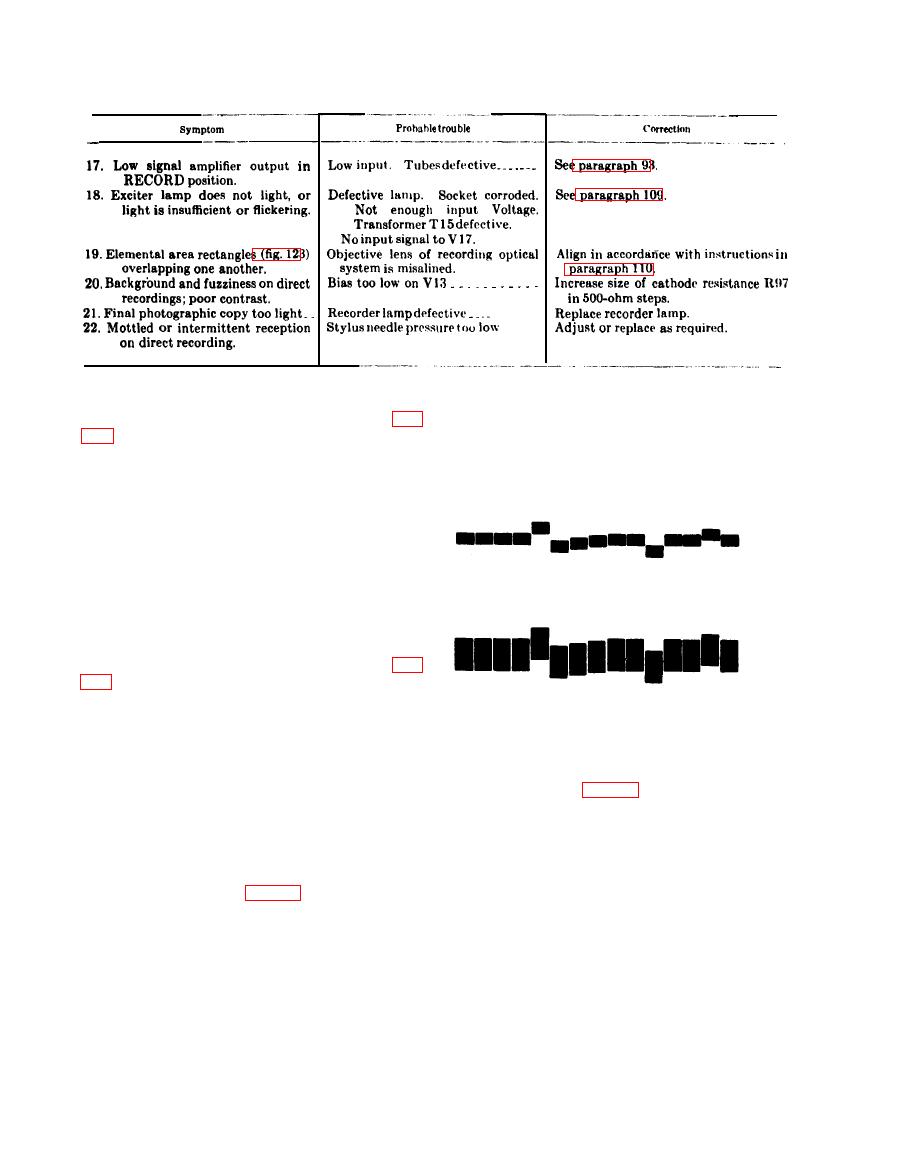

c. Irregular Skew. If the receivced copy shows

A final test should be made by using both the

an irregular skew (fig. 103), it is probable that

drum and the lead screw of another machine.

the clutch of the transmitter or receiver motor is

If the line feed trouble remains, the trouble is

slipping. This slippage often can be traced to a

probably in the motor or the optical system.

bind in the drum system. To determine whether

b. Jag or Jitters. These are the terms used to

the defect is in the transmitter or receiver,

describe irregular or saw-tooth recording of lines

examine the recorded copy with a magnifying

that should be straight (fig. 102). The trouble is

glass. If the individually recorded elemental

generally in the motor or the clutch. It can,

areas are in approximate straight alinement, the

however, originate in the drum or the lead screw.

defect is in the transmitter system. If they follow

To determine whether it is in the drum or the

the contour of the skew, the trouble is in the

lead screw, first replace the motor with one from

recorded system. When receiving on direct re-

another machine which is operating satisfactorily,

cording paper, observe the direction of the skew

and make a test run. Use a transmission test

before removing the paper from the drum. If

copy having straight lines running parallel to the

the right-hand side of the copy is skewed toward

axis of the drum. The recording of the straight

the rear of the machine, the clutch is slipping in the