TM 11-5805-424-15/NAVELEX 0967-220-9010/TO 31W2-2G-41

7-6. Data Test

a. Test Equipment and .Material.

See Maintenance Allocation Chart Section

III for test equipment.

b. Test Connections and Conditions.

(1) Remove the test MD-4(P)/G from its case and install the repaired MD-674(P)/G in its place, or remove the appropriate plug-in module from the test

MD-474(P)/G, and install the repaired plug-in module in its place

(2) Connect the equipment as shown in A and B, figure 7-1.

(3) Adjust DD-205A controls to obtain test pattern on screen.

(4) Strap together only terminals 5 and 6, on the bottom of the harness card.

(5) Strap together terminals 1, 2, and 3, on PC a ,assembly AS.

(6) Strap together terminals 2 and 4 on PC assembly All.

(7) Operate all POWER switches to the on position.

c. Procedure.

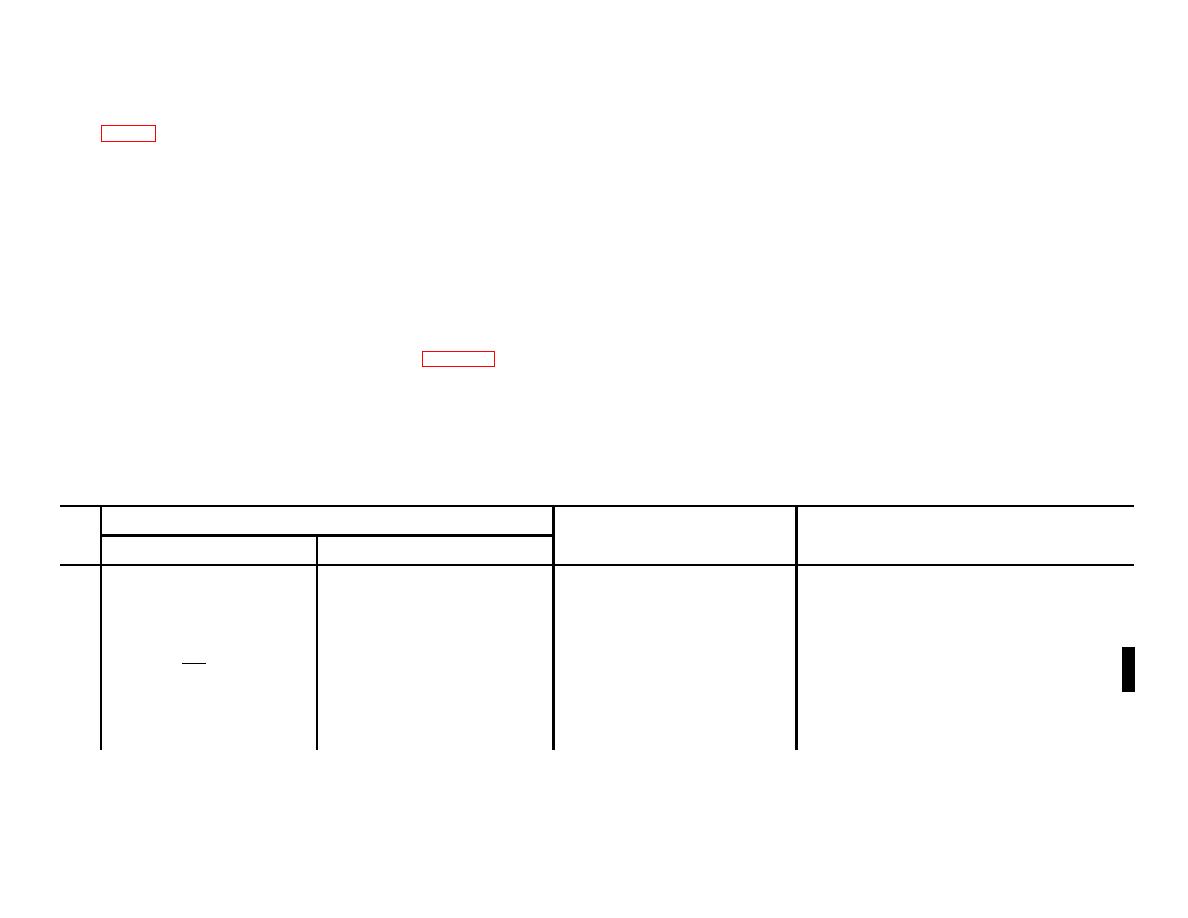

Control settings

Step

No.

Procedure

Performance standard

Test equipment

Equipment under test

1

PG-205A

BAUD RATE: As required.

a. Rotate OUTPUT LEVEL

a. ME-30A/U should indicate between

ALARM: DISABLE.

ADJ control from one ex-

-20 dbm and +3 dbm; DD-205A

INPUT: 600Ω.

CHARACTER RELEASE:

treme to the other.

SIGNAL lamp should light and

OUTPUT: 600Ω.

FREE RUN.

meter should indicate less than 3.5%

DISTORTION: OFF.

INPUT SELECT: DATA.

distortion (2% for MX-7379/G).

37.5

b. Adjust OUTPUT LEVEL

b. None.

EXTERNAL: -1200

ADJ control for 0 dbm on

PATTERN SELECTOR:

ME-30A/U, or equivalent.

REVERSALS.

c. Operate INPUT SELECT

c. Electronic Counter 5233L should indi-

BAUDS: As required.

switch to MARK.

cate as follows for each MX-73(*)/

JACK SIGNAL SELECTOR:

G ( 0.5 cps):

LOW LEVEL.

MX-7372/G: 425 cps.

Change 6

7-3