TM 11-5805-424-15/NAVSHIPS 0967-220-9010/TO 31W2-2G-41

7-5. Physical Tests and Inspection

a. Test Equipment and Materials. None.

b. Test Connections and Conditions.

(1) No connections are required.

(2) The following tests are performed with the MD-674(P)/G extended from its ferrous metal case.

c. Procedures.

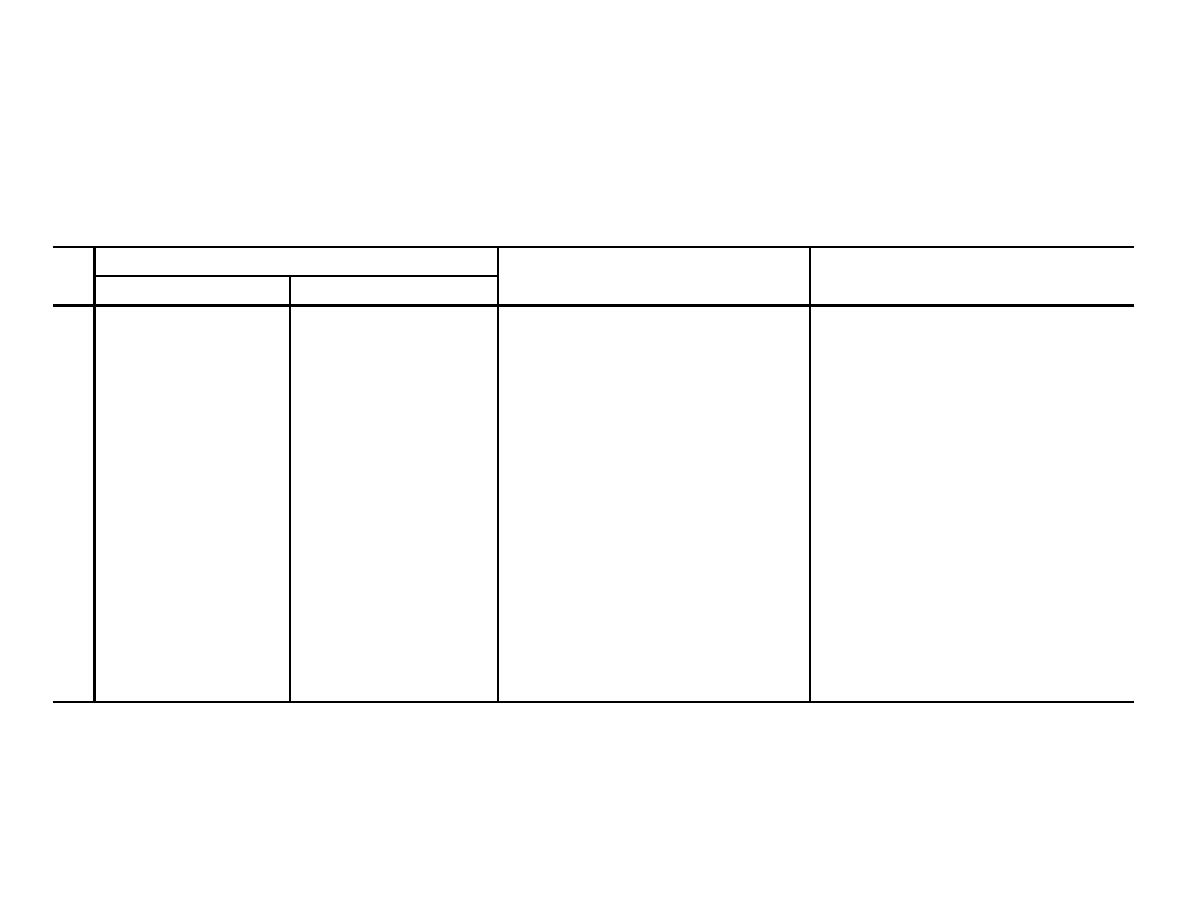

Control settings

Step

Procedure

Performance standard

Test equipment

Equipment under test

1

N/A ...............................................

Controls may be in any

a. Inspect front panel. Look for damaged,

a. No evidence of damages, loose or missing

position.

loose, or missing screws, knobs, or

screws, knobs, or parts is found.

other parts.

b. Inspect front panel and chassis (top and

b. Front panel and chassis are clean. No

bottom). Look for cleanliness, signs of

evidence of excessive wear, damage, or

excessive wear or damage, loose or

loose components or hardware are

missing components and hardware.

found.

c. Inspect condition of finish. Look for rust,

c. External surfaces intended to be painted

corrosion, and spots where bare metal

do not show bare metal. Panel lettering

is exposed.

is legible.

Note. Touchup painting is recommended instead

of refinishing. Screwheads and receptacles will

not be polished with brushes.

d. Operate each switch and control on front

d. Switches and controls operate smoothly

panel and control bracket. Look for

with positive action to indicated posi-

smooth and positive operation.

tions.

e. Inspect condition of jacks and lamps.

e. No evidence of cracks or broken parts.

Look for cracks, broken parts, and

Jack contact springs are straight and

condition of jack spring contacts.

show positive action in opening and

closing.

f. Inspect chassis; be sure PC cards are in

f. PC cards are in proper places and firmly

proper places.

seated.

2

N/A ...............................................

Controls may be in any.

Check equipment for applicable modifica-

If MWO is performed, MWO number ap-

position.

tion work order (see DA Pam 310-4 for

pears on equipment.

list of MWO's).

7-2