TM 5-2420-224-20-2

BACKHOE SWING CYLINDER REPLACEMENT

This task covers:

a. Removal b. Installation

Applicable Configuration:

General Safety Instructions:

SEE

Tools and Special Equipment:

Shop Equipment, SC 4910-95-CL-A74

Tool Kit, SC 5180-90-CL-N26

Material/Parts:

Packing (3)

Packing (2)

Caps and Plugs

Appendix C, Item 7

Rags

Appendix C, Item 32

Personnel Required: (2)

References:

LO 5-2420-224-12

Equipment Condition:

Reference

Condition Description

Page 2-22

Backhoe in Three-Point

Stance

Page 2-23

Hydraulic Pressure

Relieved

W A R N I N G

• High pressure hydraulics [oil

under 2450 psi (16,893 kPa)]

o p e r a t e t h i s e q u i p m e n t .

N e v er

d i s c o n n e ct

a n y

h y d r a u l i c l i n e o r f i t t i n g

w i t h o u t

f i r st

d r o p p i ng

p r e s s u r e t o z e r o . A h i g h

p r e s s u r e o i l s t r e a m c an

p i e r c e b o d y a n d c a u s e

severe injury to personnel.

• B a c k h o e s w i n g c y l i n d e r

w e i g h s 7 0 p o u n d s ( 3 2

kilograms). To avoid personal

injury, use a hoist or suitable

l i f t i n g d e v i c e w h e n l i f t i ng

backhoe swing cylinder.

• Fuel and oil are slippery and

c a n c a u s e f a l l s . T o a v o i d

injury, wipe up spilled fuel or

oil with rags.

R E M O V A L

NOTE

1.

Procedure is the same for both

swing cylinders except as noted.

Place backhoe in three-point

stance that will bring boom low

enough to allow access to inner

swing tower.

Backhoe must be swung to

opposite side from which swing

cylinder is removed.

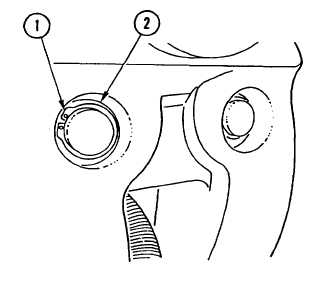

REMOVE retaining RING (1) and washer (2).

4-660

INITIAL SETUP