transceivers. Application of MWO SIG 11-2258-

ceivers TT-1B/TXC-1 through TT-1F/TXC-1.

2 to Rectifier Power Unit PP-86/TXC-1 makes

No provision is made to connect 115 volts, 60

possible the use of this unit with all models of the

cycles ac from the power unit to the transceiver

transceiver.

to start the new motor on the new or modified

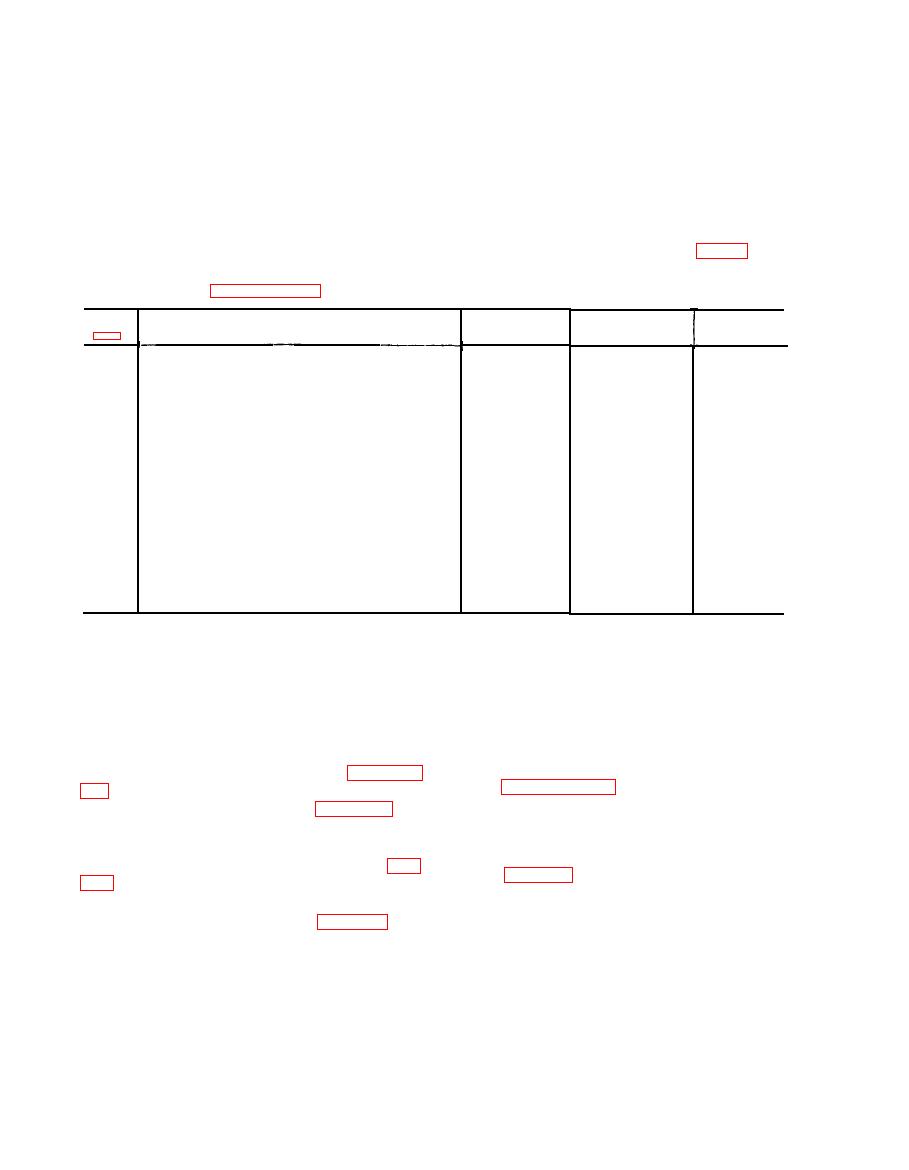

Section V. DISASSEMBLY AND LUBRICATION OF EQUIPMENT AT FIELD

MAINTENANCE LEVEL

and Lubrication Order 11-2258 (fig. 26) for

reference.

Disassemble and lubricate the items listed in the

following chart; use paragraphs 136 through 139,

Item No.

Lubrication point

Lubricant

Amount

Interval

6

PL SPECIAL

Secondary clutch dog latch pivot ------------------

1

drop -----------

Monthly

7

Dog trip arm pivot ------------------------------

PL SPECIAL

1

drop -----------

Monthly

8

Clutch rings ------------------------------------

OCW

1

or 2 drops ------

Semiannually

9

P h a s e m a g n e t armature pivots --------------------

OCW

Semiannually

drop -----------

10

Drive shaft bearings:

Sealed bearings ------------------------------

1 or 2 drops ------

Semiannually

PL SPECIAL

Unsealed

bearings---------------------------

Pack -------------

Semiannually

GL

11

Lead-screw bearings:

Sealed bearings ------------------------------

1 or 2 drops ------ Semiannually

PL SPECIAL

P a c k - - - - - - - - - - - - - Semiannually

Unsealed beatings ---------------------------

GL

12

Motor bearings:

Thin film --------- Weekly

AN/TX-1 and -1A, top and bottom bearings. -

GL

1 or 2 drops ------ Weekly

AN/TXC-1 and -1A, top bearing (no disas-

PL SPECIAL

sembly required).

AN/TXC-1B and -1C -----------------------

1 or 2 drops------

Monthly

PL SPECIAL

1 or 2 drops ------

Monthly

Synchronous rotor bearing --------------------

OCW

e. The remaining retainers and plates will slide

136. Clutch

free. It will not be necessary to remove the hub

Disassembly of the clutch for cleaning should

for cleaning purposes; the hub can be cleaned on

be performed only by qualified personnel. Or-

the drive shaft.

ganizational personnel should clean the external

f. Thoroughly clean all parts with a clean, lint-

surfaces of the clutch daily with a lint-free cloth

free cloth dampened in solvent (SD). Dry the

slightly dampened in solvent (SD). Dry thor-

parts with a clean, lint-free cloth.

oughly with a dry, lint-free cloth. Lubricate the

g. Lubricate the rings in accordance with the

clutch in accordance with the chart in paragraph

chart in paragraph 135. To reassemble, reverse

the order for disassembly.

ternally every 3 months. Refer to figures 115 and

h. Run the motor for a few minutes with the

116 for location of parts. Use the following pro-

clutch stop arm stopped. Wipe off excess oil and

cedure to disassemble the clutch for cleaning:

adjust the tension of both primary and secondary

clutches (par. 106). Run the motor for at least

15 minutes with the clutch locked up. Again

working on the clutch.

measure the tension of both clutches. If the ten-

sion of the clutches is not stabilized, repeat ad-

116) from the secondary clutch bearing (N). Be

justments and running-in process.

careful not to lose the pressure springs (0).

c. Remove the secondary clutch bearing (N) and

secondary clutch ring (Q).

a. Equipment with Sealed Bearings. Disas-

d. Remove the three flathead screws (K) from

sembly of equipment using sealed bearings (later

the retainer (H).

models) is not required for lubrication. Place 1 or