TM 5-2420-224-20-2

VALVE ADJUSTMENT

This task covers: Adjustment

Tools and Special Equipment:

Equipment Condition:

TooI Kit, SC 5180-90-CL-N26

Reference

Condition Description

Page 4-3

Valve Cover Removed

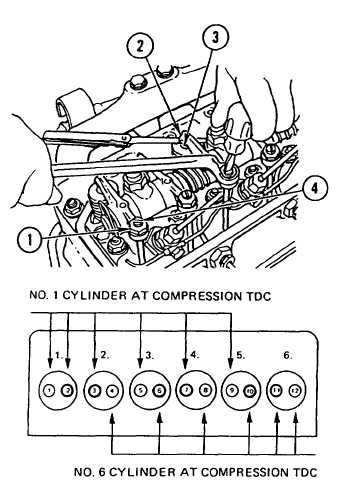

1.

Rotate crankshaft to right until rocker arms of

No. 6 cylinder overlap. No. 1 cylinder will now

be at Top Dead Center (TDC).

C A U T I O N

Do not make valve adjustments

u n t i l e n g i n e h a s c o o l e d t o

below 122° F (50° C) to prevent

damage to equipment.

2.

Using feeler gage, check valve clearance.

Clearance for intake valves 2, 3, and 7 is

0.008 in. (0.20 mm). Clearance for exhaust

valves 1, 5, and 9 is 0.012 in. (0.30 mm).

3.

If adjustment is required, loosen nut (1) and

insert feeler gage between rocker arm (2) and

pad (3). Turn adjusting screw (4) until rocker

arm just touches feeler gage. Tighten nut (1)

and recheck clearance.

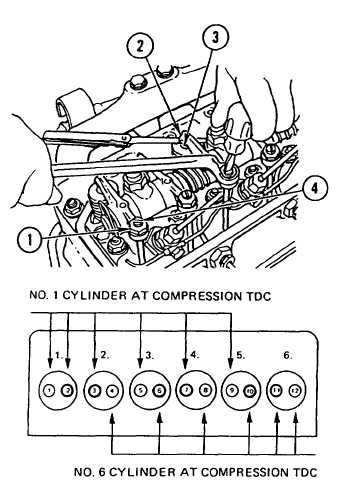

4.

Rotate crankshaft to right until rocker arms of

No. 1 cylinder overlap. No. 6 cylinder will now

be at TDC.

5.

Repeat steps 2 and 3 for intake valves 6, 10,

and 11 and exhaust valves 4, 8, and 12.

NOTE

Follow-on Maintenance:

Install valve cover (page 4-3).

4-5