TM 11-7440-278-14

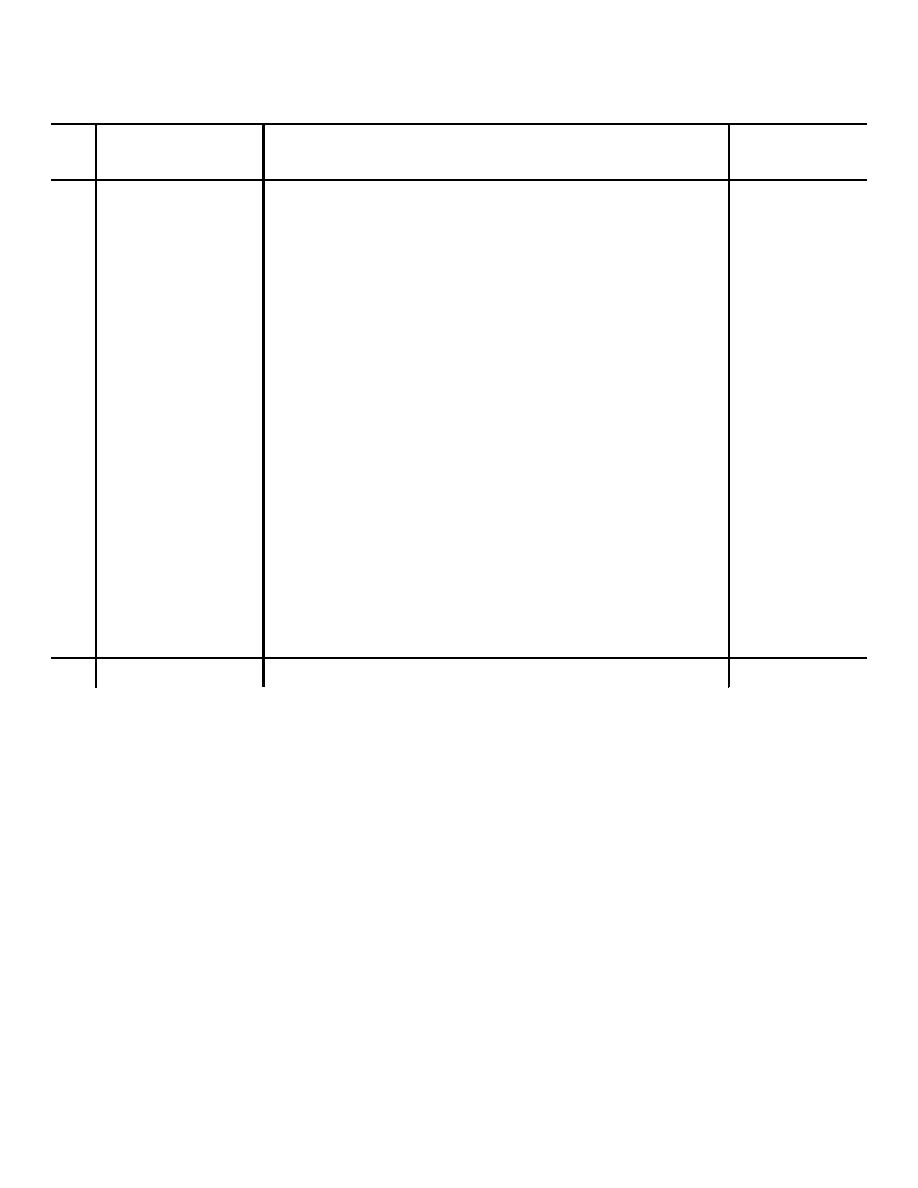

Table 4-1. Organizational Preventive Maintenance Checks and Services Weekly Schedule

Equipment will be

Item

Item to be

reported not ready

No.

inspected

Procedures

(red) if:

1

EXTERNAL finish of

Paint blistered, pitted and flaking areas and bare metal spots.

assemblage

2

Grounding system ...........

Remove corrosion from ground rods and ground terminals.

Tighten connections.

a. Clean and touchup as necessary.

3

Entrance door..................

b. Tighten loose screws and bolts.

c. Lubricate door locks and latches with Grease, Graphite, Aircraft (GGA);

lubricate hinges with Lubricating oil, General Purpose Preservative

(PL Special) or Lubricating oil, Engine (OE-30).

d. Inspect gaskets and cement loose gaskets into place.

a. Lubricate cover hinges with PL-Special or OE-10.

4

Signal and power en-

b. Touch up paint.

trance panel

5

Power and signal cables

Inspect power and signal cable assemblies for damage or loose connectors.

Repair or replace as requi red.

a. Tighten loose screws and clips.

6

Signal, power and light-

b. Inspect cables for damage or loose connections. Repair or replace as

ing system ducts and

cables in interior of

required.

shelter

7

Shelter lighting circuits

Tighten loose connections or mounting screws. Replace or repair damaged

fittings or switches as required.

a. Tighten loose mountings bolts, nuts, and screws. Replace any missing

8

Equipment mountings

fasteners.

b. Inspect all mounting hardware for dama ge and repair or replace as

required.

9

Portable generator set

Perform required preventive maintenance checks in accordance with

(if used)

applicable TM.

10

Air conditioner/heaters

Perform required preventive maintenance checks in accordance with

applicable TM.

11

LS-147/F1 .......................

Perform required preventive maintenance check and services

(See TM 11-5830-221-12).

12

Clock ...............................

Check to see that clock is operating properly.

Section IV. TROUBLESHOOTING AND MAINTENANCE OF AN/MYK-8(V)(*)

4-7.

Troubleshooting Procedures

4-8.

Maintenance of AN/MYK-8(V)(*)

Organizational level troubleshooting is based

on

Organizational maintenance of the AN/MYK-8 (V) (*) is

symptoms that may occur during operation or during

the

restricted to those actions specified by the maintenance

post-installation operational check.

Refer to

the

allocation chart (appx D). Refer to the applicable manual

applicable manuals listed in appendix A

for

listed in appendix A for specific maintenance procedures.

troubleshooting procedures.

Section V.

MAINTENANCE OF HYDRAULIC POWER UNIT

show some of the fundamental features of a good power

4-9.

General

unit.

The hydraulic power unit (not installed in OL-88

(V)3,/MYK-8(V)) generally consists of a hy-draulic pump

4-10. Oil Change

or pumps, electric motor, relief valve, suction strainer or

Even if high-grade oil was installed at start-up, oil does

filter, and a reservoir for supply of oil. The power unit

become contaminated in time. Watch for discoloration,

shown in figure 4-1 typifies one of a series of power

foaming, or change in viscosity.

units. While there are variations from this basic unit, this

does

4-2