b. Secondary Clutch (fig. 26). No parts need be

Transceiver TT-1(*)/TXC-1 under the lead screw

removed or any adjustments disturbed to clean

shaft.

the dog latch cam plate. Clean the cam plate

with a lint-free cloth dampened with solvent (SD).

S e t AN/TXC-1(*)

Any portion which cannot be reached easily can

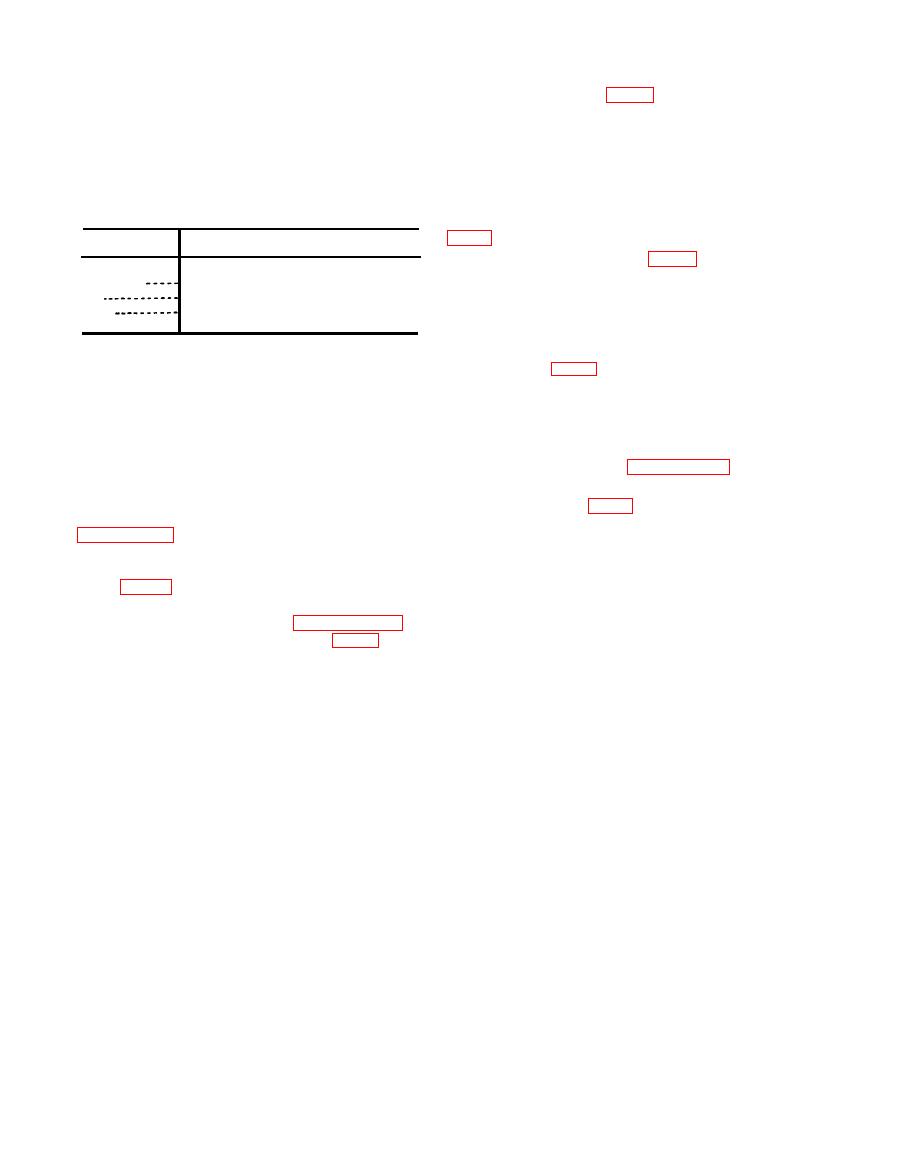

The following chart lists the lubricating ma-

be cleaned by covering an orangewood stick with

terials necessary when servicing Facsimile Set

the dampened cloth. Dry thoroughly with a

AN/TXC-1(*).

lint-free cloth. Lubricate according to LO 11-2258

Standard

nomenclature

Symbol

motor worm and gear with a lint-free cloth damp-

PL Special

Oil, Lubricating, Preservative, Special.

ened with solvent (SD). Clean in between the

Grease, Aircraft and Instruments.

GL

teeth by covering an orangewood stick with the

OCW

Oil, Clock and Watch.

dampened cloth and running it between the teeth.

Dry with a lint-free cloth. Lubricate according

to LO 11-2258 (fig. 26). To perform this operation

Clean the parts thoroughly before applying

on Facsimile Sets AN/TXC-1B and -1C, first

lubricant. Be sure that the parts are free of dirt,

remove the gear case cover.

dust, corrosion, and old lubricants. The following

paragraph outline the methods, procedure, and

materials to be used when cleaning equipment

preparatory to lubrication. The instructions are

The lubricants listed in paragraph 45 may be

applicable in common to Facsimile Sets AN/TXC-

used in all temperature. The intervals listed in

1, -1A, -1B, -1C, and -1D unless otherwise noted.

the lubrication order (fig. 26) are based on 8-hour

For additional information on cleaning, refer to

normal daily use. When the equipment is used

more than 8 hours daily, or is used in tropical

nance.

climates, lubricate it more often. For example,

a. Lead Screw, Guide Rail, Drum Shaft, and Key-

if the equipment is in use 16 to 20 hours daily,

lubricate after each 3 hours of operation. The

cleaning and lubricating these items. Thoroughly

lubrication periods can be determined by frequent

clean the parts as outlined in paragraph 41e.

Lubricate as outlined in LO 11-2258 (fig. 26).

inspection of all lubrication points.

Section IV. WEATHERPROOFING

spray method of applying moistureproofing and

fungiproofing and the supplies and equipment

a. Genaral. When electronic equipment is

The following

required for this treatment.

operated under the severe climatic conditions

problems may be encountered:

which prevail in the tropical, arctic, or desert

regions, it requires special treatment and mainte-

(1) Resistors, capacitors, coils, chokes, trans-

nance. Fungus growths, insects, dust, corrosion,

former windings, etc., fail because of the

salt spray, excessive moisture, and extreme

effects of fungus growth and excessive

temperatures are harmful to most materials.

moisture.

b. Tropical Maintenance.

Because fungus

(2) Electrolytic action often visible in the

growth, insects, corrosion, salt spray, and excessive

form of corrosion takes place in resistors,

moisture affect most materials in a harmful

coils, chokes, transformer windings, etc.,

manner, a special moistureproofing and fungi-

and eventually causes breakdown.

proofing treatment is used and, if properly applied,

(3) Hook-up wire insulation and cable insula-

it provides a reasonable degree of protection.

tion break down. Fungus growth accel-

Refer to TB SIG 13 (Moistureproofing and Fungi-

erates deterioration.

proofing Signal Corps Equipment), and TB SIG 72

(4) Moisture forms electrical paths on ter-

(Tropical Maintenance of Ground Signal Equip-

minal boards and insulating strips, and

ment) for detailed descriptions of the varnish-

causes flashovers and cross talk.