TM 9-1220-238-14

control time in addition to the time required to perform

be used:

specific maintenance functions identified for the tasks

C Operator/crew

authorized in the maintenance allocation chart. This time

O Organizational

may be the established time standard developed through

F Direct support

maintenance engineering analysis, or can be derived from

H General support

the calculation of a statistically weighted time estimate

D Depot

incorporating the optimistic (a), most likely (m), and

e. Work Measurement Time. The active

pessimistic (b) estimated for the work to be accomplished

repair time required to perform the maintenance

using the formula:

function will be included directly below the symbol

t = a+4m+b

identifying the category of maintenance. The manpower

6

figures will be developed under conditions (real or

This time will be expressed in man-hours and carried to one

simulated) corresponding to those that would be

decimal place (tenths of hours).

considered normal for TOE units operating in the field.

f. Column 4. Tools and Equipment. This column

The skill levels used to obtain the measurement times

will be used to specify, by code, those tools and test

will approximate those found in typical TOE units.

equipment required to perform the designated function.

Active repair time specified is the average aggregate

time to restore an item (subassembly, assembly,

NOTE: A table, suitably coded and explained, listing

component, module, end item or system) to a

the tool, test, and support equipment required by the

serviceable condition under typical field operating

level to perform the maintenance functions will be

conditions. This time includes preparation time, fault

included as a supplement to the MAC.

isolation/diagnostic time, and quality assurance/quality

g. Column 5. Remarks. Self-explanatory

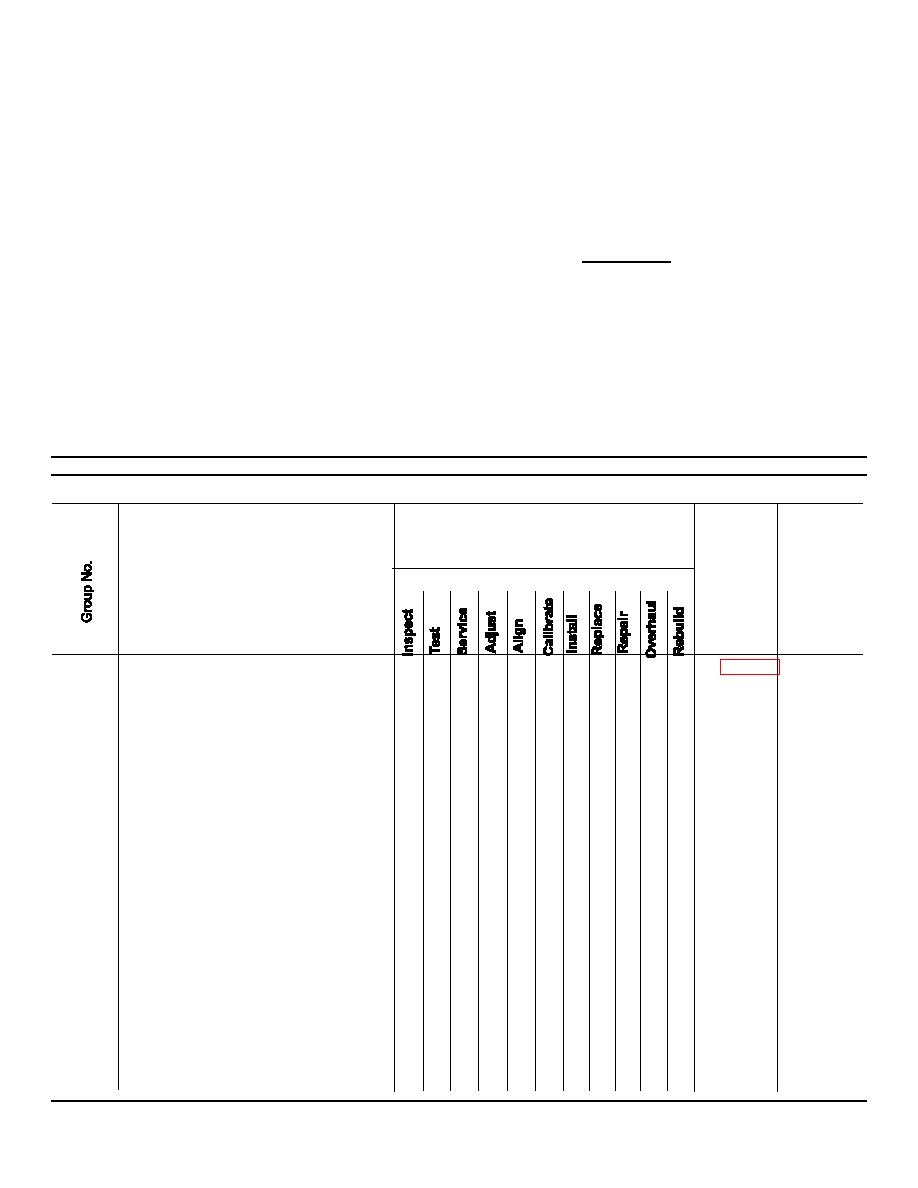

Nomenclature of End Item or Component BOARD, PLOTTING, FLASH RANGING, M18 W/E

SECTION II. MAINTENANCE ALLOCATION CHART

(1)

(2)

(3)

(4)

(5)

Functional Group

Maintenance functions

Tools and

Remarks

equipment

A

B

C

D

E

F

G

H

I

JK

1

Board, Plotting

C

C

CF

D

See Table C-1

M18 W/E

0.1

0.2

0.2 0.2 5.0

1.1

Board, Plotting

C

C

0

D

M18

0.1

0.2

0.2 4.5

1.1.1

Support Assembly

C

C

F

Group

0.1

0.2

3.0

1.1.1.2

Roller Assembly

C

F

01

0.2

1.1.1.3

Frame Assembly

C

C

F

0.1

0.1

1.0

1.1.2

Brace Assembly

C

C

F

Group

0.1

0.1

0.5

1.1.2.1

Brace Assembly

C

C

F

0.1

0.1

0.5

1.1.3

Scale Assembly

C

C

F

FF

0.1

0.1 0.3

0.3 0.5

1.1.4

Bracket Assembly

C

C

FF

Assembly

0.1

0.1

0.2 0.2

1.1.5

Bracket Assembly,

C

C

FF

Rest

0.1

0.1

0.1 0.2

1.1.6

Bracket, Vernier

C

C

F

FF

Assembly

0.1

0.1 0.6

0.5 1.0

1.1.7

Spindle Assembly

C

C

C

0.1

0.1

0.1

1.1.8

Leg

C

C

C

0.1

0.1

0.1

1.1.9

Disk, Plotting

C

C

O

0.1

0.1

0.2

1.2

Chest, Packing

C

C

CF

D

(Reusable Container)

0.1

0.1

0.1 0.2 1.5

C-2